Will

You Still Be in Business 10 Years From Now?

The answer may depend on your automation strategy.

an opinion piece by Dan McClenathen, President, Advanced

Machines, Inc.

(posted 02/16/2004)

Future

labor shortage … a manufacturing dilemma

The economy is beginning to come back but will you be

able to find enough people to staff your factories and

machine lines in the future? Are you thinking about

five to ten years from now? If so, the picture

is not very rosy. By the year 2007, the big bubble

of ‘‘Baby Boomers’‘ will begin to retire. ‘‘Baby Boomers’‘

comprise the largest demographic group in the U.S. today.

This

problem is already beginning to raise its ugly head.

I am aware of some manufacturing companies in northeast

Indiana that are suffering from such a labor shortage

that they actually have picnics on the factory front

lawn. They invite anyone they can to come to the

picnic. After the people are finished eating,

they are invited to tour the facility. At the

end of the tour, they are asked to complete an application.

Consider

the fact that most of today’s younger people do not

want to work in a factory. They do not want to

work on an assembly line or feed parts into a machine

that entails getting their hands dirty. They want

to work in offices or on computers; much different from

the previous generations who built this country into

the industrial giant that it is today.

When considering a career choice, people external to

manufacturing think of the bad factory working conditions.

Many of today’s factories may be brightly lit, clean

and filled with a mix of digital manufacturing technology,

but this message has not been communicated to the public.

Most parents, kids, and educators today think of manufacturing

as dingy, dark, dangerous, and dead end.

Politics

… can the government help solve labor issues?

The economy of this country depends largely upon manufacturing

right here in the good old USA. Even our government

has recognized that there is a future labor shortage.

They have removed the cap on how much a retiree can

now earn and still collect their Social Security.

This was unheard of 10 years ago. But, is that

enough? Can the government respond to a problem

of needing more people to work in factories? Will

they grasp the seriousness of this problem? A

failing manufacturing industry will touch all people

and all parts of our society.

After

World War II, manufacturers were the main employers.

However, in the last few decades, they have suffered

from overseas competition and a shortage of skilled

workers. Manufacturing has become less attractive than

it was in the past. I have heard it said that

manufacturing, as we know it today, is ‘‘one generation

from extinction’‘. Either we prepare for the future

labor shortage or we will not be in business.

Some

companies are thinking about going overseas to attract

help. Please consider the language barrier; communication

is important. Things can change very quickly on

a shop floor. Most ‘‘on the fly’‘ changes are

handled verbally. Those that have tried foreign

hiring plans have not had much success. They have

spent a lot of money but have little to show for their

efforts in the end.

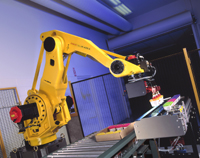

Advanced

Machines has recently begun to integrate robots into

machining cells for one of its customers that is bringing

production back from Mexico. It seems cheap labor

comes with many business, quality, and logistical problems.

And, after one year, how much does a robot really cost?

Very little.

Where else

should we be looking for solutions … think systems integrators.

We must take charge of our own destiny. System

integrators are the new white knights capable of saving

our manufacturing base. We are standing on the

edge of a forced transition to a robot-manufacturing

arena. Any company that chooses to ignore the

signs to heavily introduce robots into their plants

to cover for the future labor shortage may go out of

business. Are you able to see the need for the

future robot evolution and plan for it before the labor

shortage becomes a crisis?

Robots

do not go on vacation, take lunch hours, complain, get

overtime pay, quit, need 401-K programs, health, life

or disability insurance, unemployment compensation,

social security, or present any of those human resource

related issues. The average robot costs as much

as one person does for a year. However, after

the second year, the cost decreases dramatically.

Robots can run for many years with little maintenance.

I

am aware of a Tier One Automotive parts manufacturer

that recently received an order to build parts because

another supplier could not keep up with the demand that

the manufacturer required. It seems this other

supplier built a new small plant to manufacture automotive

parts but, when the factory was completed, not enough

people could be found that were willing to work.

We designed and integrated a full line of machines and

robots so our customer could build the parts without

any operators on the line. People bring raw parts to

the line and other people take finished parts, already

packaged, from the line.

Lights

out manufacturing … what does it mean?

Machines do not need lights to manufacture parts like

humans do. ‘‘Lights out manufacturing’‘ is an

old term that in the past had a lot of hype and questionable

results. Those that did a good job integrating

this concept into their shops today swear by it.

Those that merely went through the motions will swear

at it.

I

have been a part of programs where a Fortune 500 company

literally sectioned off its shop floor into quarter

sections. One section at a time was converted

to ‘‘lights out manufacturing’‘. There were approximately

320 employees on the floor before the integration to

CNC machines and robots. When completed, there

were hundreds fewer employees required. They planned

well and executed well.

Conversely,

I have also been a part of programs where the companies

treated ‘‘lights out manufacturing’‘ more as the latest

fad, i.e. everyone else is doing it so why don’t we

try. The results were poor and, of course,

they blamed it on the concept. ‘‘We tried it and

it just doesn’t work’‘.

For

the ‘‘lights out manufacturing’‘ practice to save us

in the future, we must approach it with the goal of

doing as much as possible without any labor. Manbir

Sodhi, a professor of industrial and manufacturing engineering

at the University of Rhode Island, Kingston, claims

economics, labor shortages, and improved technology

will help drive ‘‘lights out manufacturing’‘ growth.

Today

we have better technology and better skilled integrators

to see that what we start can be done. Some companies

are starting by converting over one section of the plant,

or one shift, to ‘‘lights out manufacturing’‘.

They know the future is coming but may not have the

capital to totally build a new facility dedicated to

‘‘lights out manufacturing’‘.

Are

robots right for you?

As with many business strategy decisions, this is a

big decision that in the end must be made by you alone.

But in making that decision, consider the benefits of

using robots. Robots do not get bored or concerned

about working conditions. In fact, over time,

robots can perform many tasks more efficiently than

people. Additionally, they do not get sick or

need to rest. Consider those tasks that are dangerous

with too much heat or fumes from welding. While this

environment may be hostile to humans, robots never complain.

Robots

can, among other things

- Assemble

parts,

- Handle

dangerous or heavy materials,

- Spray

chemicals or paints,

- Inspect

parts,

- Store

finished parts, and

- Cut

or polish parts.

You

dream it up and let an experienced integrator show you

how it can be done with a robot.

Is

integration right for you?

James B. Swartz wrote in The Hunter and the

Hunted, ‘‘Our competitive environment changes

rapidly. If you want to survive, you have to stay

on top of changes. Otherwise, you will become

the prey to your competitors. Hunters continuously

change and learn; anyone who doesn’t becomes the hunted

and sooner or later will be devoured.’‘

In

addition to the future labor shortage, let us also look

at ‘‘Robot Return on Investment’‘ (ROI): First

of course you need the Capital Investment to have the

integration in place and running then can consider:

- Total

Personnel Savings

- Productivity

increases in unit output

- Ergonomic

Savings including legal claims brought against you

- Time

savings of changeovers – manually, it can take hours

whereas automatically, it can take minutes

- Total

productivity increases

- Warranty

savings i.e., less 8D type of work may be required

to protect your customer

Integration

has the potential to lower costs, improve quality and

timing responsiveness, and tighten the supply chain

in and out of your facility.

In

selecting a system integrator, consider the following:

- What

kind of relationship do you want? This is really

a partnership.

- Find

a company that understands and has experience in your

industry.

- Does

their company understand the application you want?

- Let

the integrator propose the solutions. Then you

choose which is best for you.

- Do

they have the skills and resources needed to execute

the project?

- Are

they large or small enough to complete the project

on time and efficiently?

- Check

references. How did they perform for others?

- How

about technical support? Will they be available

after the project to help if any snags arise?

- Documentation

is very important.

- Do

they have simulation capabilities

? Can they actually show how the integration

design will work before they build it?

Machine

vision

This is another advantage of integrating human to machine

to machine to human systems. Vision systems are a major

quality control tool. Vision systems can inspect

for:

- Part

location and orientation

- Optical

Character Recognition and verification

- Surface

defects

- Plastic

short fills

- Bar

code reading

- Surface

flatness

- Discoloration

- Precision

Gauging

These

systems can then export the gathered data to an Excel

spreadsheet, enabling automatic Statistical Process

Control (SPC). Every step of a manufacturing

process can be validated.

In

closing

Countries that have a strong manufacturing base prosper.

If we are to continue to be a leader in manufacturing,

we must prepare for the shortage of good industrial

employees when the ‘‘Baby Boomers’‘ begin to retire.

Advanced Machines, Inc. believes the best way to prepare

for the future labor shortage is through new system

integration methods. Start today by contacting

a system integrator company that knows which robotic

improvements can help you stay in business 10 years

from now. And, remember to ask them to show you

a total machine line simulation of

how your line will actually function before it is built.

|