|

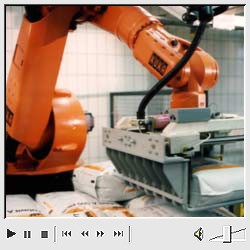

Handling of animal fodder sacks

Starting point / Task definition

BASF was looking for an automated palletizing solution

for its vitamin A concentrate, which is used primarily

in animal food, but also in food for humans and in pharmaceutical

products. The main reasons for this conversion from

manual to automated handling were a desire for higher

productivity and better working conditions for employees.

Implementation / Solution  The automated system is built around a KUKA KR 125 six-axis

robot equipped with a fork gripper. A decisive criterion

in the selection of this automated system was the floor

space requirement. The space which was available was relatively

small, and was also not very high. During handling operations,

only three centimeters remain between the top of the robot

and the ceiling when the robot reaches its highest position. The automated system is built around a KUKA KR 125 six-axis

robot equipped with a fork gripper. A decisive criterion

in the selection of this automated system was the floor

space requirement. The space which was available was relatively

small, and was also not very high. During handling operations,

only three centimeters remain between the top of the robot

and the ceiling when the robot reaches its highest position.

Originally BASF had planned to use a

palletizing machine, up until then the standard solution

for such applications. The major argument against this,

however, was its height requirement, which would have

necessitated constructing a pit. Besides the additional

expense this would have involved, such a design would

have been questionable from a food technology point

of view, if only because of the difficulty and expense

of cleaning. Additional arguments in favor of the robot

were its short cycle time and good figures with respect

to repeatability and flexibility.

The vitamin A is put into 25 kg sacks.

When preparing shipments that will be sent overseas,

BASF additionally places each sack in a cardboard box.

The sacks and boxes are carried on conveyor belts through

a weighing and labeling station before arriving at the

robot. Just before reaching the robot, the goods are

transferred from the conveyor belt to a roller conveyor.

In this way, the vision system can report to the KR

125 that a container has arrived, and the robot can

reach between the rollers of the conveyor with the forks

of its gripper, and lift the sack without damaging it.

The robot then gently stacks the bag on a pallet, which

is located on the outgoing roller conveyor. The robot

can also handle cardboard boxes using the same fork

gripper that is uses for the sacks.

System components / Scope of supply

KUKA KR 125 robot

PC-based KUKA robot controller, including control panel

with Windows interface

Fork gripper

Incoming and outgoing conveyor systems

Safeguards

Weighing and labeling station

Robot programming

Test setup to verify system functions at an early stage

Commissioning

Supplied by KUKA systems partner Koch-Industrieanlagen

GmbH, Dernbach near Dierdorf, Germany.

Results / Success

High repeatability

The high repeatability of the KR 125

means that it can handle the sacks and boxes gently

and stack them precisely, which plays a large part in

preventing transportation damage.

Remarkable flexibility

Thanks to the robot’s flexibility,

the user can switch quickly at any time between different

container forms and stacking patterns. For example,

the robot “knows” how to make composite

stacks of sacks and column stacks of cardboard containers.

Compared to a conventional palletizer, which sometimes

actually has to be modified in the case of varying containers

or conditions, with the KR 125 all one has to do is

choose the appropriate program from those stored in

the robot controller. To simplify this procedure even

further, BASF had a lever installed which makes it even

easier to select either one of the two standard programs,

even if the operator has practically no prior knowledge

of the system. Other programs are also provided, for

example for varying the number of layers depending on

the forwarding route.

Short cycle time

At a cycle time of ten seconds, the

KR 125 stacks approximately 30 tonnes of vitamin A concentrate

per shift. The capacity of the system is designed for

growth, and a cycle of seven to eight seconds could

be implemented. The gain in productivity from using

a robotic cell becomes apparent if one considers that

palletizing one sack previously took a whole minute.

Rapid payback

Since the introduction of this automated

palletizing system, BASF has required two fewer workers

in this area, thus achieving a relatively short payback

period. The high availability of the robot is also important

here; BASF is reinforcing this by sending some of its

own employees for training by the KUKA systems partner.

|